|

Weifang Estye Imp&Exp Co.,Ltd.

|

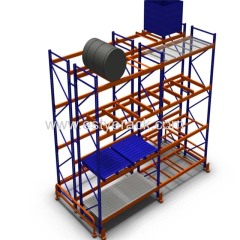

plate storage racks for cold warehouse

| Price: | 120.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1, high qualily of steel

2, making the best of the warehouse space

3, prompt delivery

4, powder coating sprayed and lead free.

5. easy install

Common components of selective rack include the following:

Load beams (also called step beams or box beams).

Most Step Beams are roll formed members with a step along the top inside edge. This step is used to hold any load support components such as pallet supports or wire decks.

Brade | ESTYE | ||

Raw-Material | High-Quality Q235 Cold rolled steel | ||

Color | Upright frame is bule,Beam is orange,can be customized. | ||

Standards Size | L2300*D1000*H4500 and size can be customized according to your requirment | ||

Height | 1500-8000mm or Customized; | ||

Wide/Depth | 400-1500mm or Customized; | ||

Length | 1500-3200mm or Customized; | ||

Upright-Section | 80*60*1.5/1.8/2.0mm,90*65*1.5/1.8/2.0mm, 100*70*2.0/2.5mm, 120*95*2.0/2.5mm ect | ||

Loading Capacity | 1000~6000kgs or 2200~13200lbs | ||

Beam-Section | 80*45mm, 100*45mm, 120*45mm, 140*45mm,160*45mm,180*45mm etc. | ||

Treatment Surface | Powder coated | ||

Packing Term | Air bubble,Wooden Case,etc. | ||

Box Beams have no inset steps; instead have four flat sides like a box. All load beams typically mount onto an upright frame column with integral rivets or hooks. Some systems utilize an extra clip or bolt to lock the beam to the upright.

Upright Frames (also called upright columns or uprights) vary in size and design depending on load requirements, and styles. The most common upright column is produced by roll forming flat coil stock steel into a modified "C" shape with returns. This style is often referred to as open-back roll-formed columns. Holes or slots are punched during manufacturing up and down the column at standard intervals so that the load beams can be mounted into the upright columns. Upright frames can also be constructed utilizing structural C shapes for columns. Structural uprights have an increased weight capacity over roll formed uprights.

Diagonal Braces and Horizontal Brace commonly referred to as upright frame lacing is usually welded between two upright columns to form selective upright frames. The lacing may be bolted to the columns in some cases.

Pallet Supports are roll formed channels that are placed front to back between the load beams to support pallets.

Wire Decking is commonly used as a safety measure on selective pallet rack to prevent pallets or the products stored on them from falling through the rack structure. Wire mesh decking comes in various thicknesses and mesh dimensions. Wire mesh construction also allows for easy identification of shelf contents and prevents dirt and other debris from accumulating on the shelves because of the holes in the mesh. Most wire mesh decking has U-shaped channel supports, also known as struts, to support the load. With this waterfall decking, the wire mesh extends across the top and down the front of the beam to provide more support, and is more desirable in the marketplace. Reverse waterfall decking can provide containment of a loose product to prevent the product from falling behind the rack system. Lay-in decking rests inside the step of the beam, and wire mesh does not waterfall over the beam. Some types of decking are manufactured with solid metal instead of wire mesh. Even though the solid decking provides a greater distributed weight capacity, it is discouraged by fire inspectors because sprinkler systems cannot spray through the shelves to levels below.

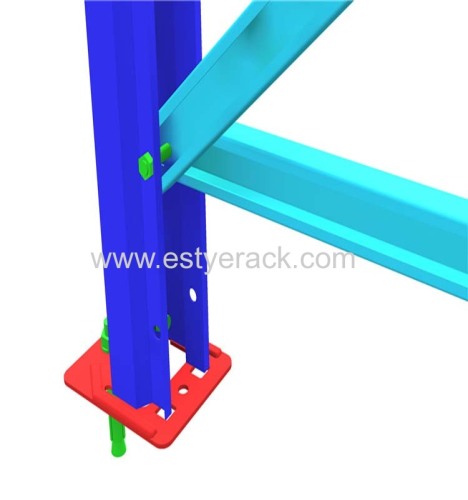

Footplates, also known as footpads or base plates, are at the base of columns and serve as anchors to give the rack more stability: anchor bolts are inserted through the base plate's holes to attach the column to the concrete floor. Footplates are made of thicker steel and in some geographic locations; they must be of a certain size and seismic rating. Footpads increase the pallet rack's overall stability and weight-bearing capacity.

Shims are used when the uprights are resting on uneven floors; the shims, equal in size to the base of the uprights, are installed beneath the uprights to level the rack.

Row spacers are sometimes used if uprights are arranged in back-to-back rows; the spacers are mounted between adjacent columns to ensure that the rows are kept straight and to give the pallet racks even more strength and steadiness.

Wall ties may be used for further support if the uprights are arranged in a row along a wall.

Column protectors, also known as post protectors, are protective shields that can be installed around the base of an upright to minimize damage where forklifts might hit the upright. Damage to the base of a column can weaken the entire frame and could cause it to collapse. Column protectors are made of various materials such as polyethylene, ductile iron casting, and other durable materials.

Guard rails are installed to increase protection for upright columns and for human safety when platforms or steps are attached to pallet racks.

Uprights: consist of a series of keyhole slots on the outside edges used to connect beams. Two upright frames are needed to construct one section of racking; however you can add on additional sections with just one upright frame. Weight capacities for upright frames are shown by how much the entire bay can hold.

Beams: are used to create levels to store pallets or other storage items. Beams are a tubular steel design featuring a notched out "step" that is used for accessory pieces like wire decking or cross bars. Weight capacities of beams are commonly expressed as a pair.

Wire Decking: can add to the function of your pallet racking, allowing you to use the levels for items other than palletized loads.

Rack Accessories: numerous accessories are available as well - row spacers, column protectors, pallet supports, and more.

FAQ

Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Qingdao/Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→Shipping

Q: What's your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.

Q: Does estyeracking have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products of estyeracking to fit at least one 20ft. container, which is about 15 tons.

Q: How does estyeracking charge tooling fee (cost of opening new mold)?

A: For the production of necessary tooling requirement, estyeracking charges the cost before the first order for opening new mold, and the cost will be partially or fully refunded after certain quantity of orders.