|

Weifang Estye Imp&Exp Co.,Ltd.

|

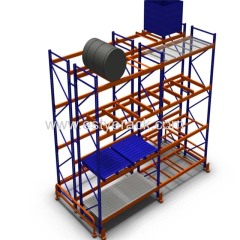

heavy duty pallet warehouse rack

| Price: | 50.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Our heavy-duty warehouse racking system is designed to provide maximum strength and durability for storing heavy and bulky items.

1,Material and Construction: Our heavy-duty warehouse racking system is constructed using high-quality steel components. The upright frames are made of thick, robust steel to provide superior strength and stability. The horizontal beams are designed to withstand heavy loads and are available in various lengths to accommodate different storage needs.

2,Load Capacity: Our heavy-duty warehouse racking system is specifically designed to handle heavy loads. The load capacity can vary depending on the specific configuration and beam length, with capacities ranging from several thousand pounds to multiple tons per level. The load capacity can be further enhanced with additional support accessories such as wire mesh decking or pallet support bars.

3,Configurations: Our heavy-duty warehouse racking system offers various configurations to suit different storage needs. It can be customized with adjustable beam heights and depths to accommodate different pallet sizes and optimize storage space. Additional accessories such as dividers, shelf panels, and bins can be added to further organize and maximize storage efficiency.

4,Selectivity and Accessibility: Our heavy-duty warehouse racking system provides high selectivity, allowing for easy access to individual pallets. Forklifts or other material handling equipment can easily maneuver within the racking system to retrieve or store pallets. The open design of the racking system ensures clear visibility and easy access to stored items.

5,Safety Features: Safety is a priority in the design of our heavy-duty warehouse racking system. It includes safety accessories such as rack protectors, load stoppers, and safety pins to prevent accidental dislodging or damage to the racks. Safety signage and floor markings can also be added to enhance warehouse safety.

6,Easy Installation and Maintenance: Our heavy-duty warehouse racking system is designed for easy installation and maintenance. It typically uses bolted connections for quick assembly and disassembly. Regular maintenance, including inspections and repairs, is recommended to ensure the system's longevity and safe operation.

Overall, our heavy-duty warehouse racking system is a reliable and efficient storage solution for warehouses and industrial facilities that require robust and durable storage options for heavy and bulky items.

It is made of the upright frames and beams.The upright frame is made up of two uprights,row bracing,diagonal bracing and nylon screws.With the insert structures,it can prevent the imbalance for the loose of the screws.On the upright,there is two straight line of tear drop hole with 50mm between two holes.So the beam can be adjusted every 50mm.The uprights are rolled into the shape with 13 roller procedures after being punched in automatic products lines.The box beam is composed of two enclose C-profiles weld with one time punch shaped connector in both ends.It is a very economic beam with a high resistance on torsion and deflection.The beam and the upright is connected with the safety locker ,which can protect the beams from dropping off.It is safe and simple structures.The clients can choose the items of the pallet racking according to the following factors:the load capacity of the pallet,pallet size,warehouse space,the lift height of the fork man.

Name | Teardrop (US) Pallet Rack | Material | Steel |

Depth | Upright 1.5;2.0;2.5mm | Weight Capacity | 1000-1500 Kg Per Pallet |

Width | Customized | Height | Customized |

Frame Structure Type | 3"*3" Welded & Bolted Upright frame with Baseplate | ||

Beam Type | 3"-6" Step Beam | ||

Beam Connector Type | SP & SL Safety Locker | ||

Surface finish | Powder coating; Galvanized; Hot Dip Gavanized | ||

Application Environment | Normal Temperature or Cold Room (Max -40C) | ||

Certification | CE | ||

Free Sample | Available (Delivery Cost on Buyer) | ||

OEM | Available | ||

Selective Racking takes up the least amount of space and can be configured to almost any size needed. This system allows immediate access to any stored pallet loads without having to move any other pallets. This is the least cost racking selection on a per pallet cost. It also has the least storage density per square foot compared to double deep, push back, drive-in or pallet flow.

FAQ

Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Qingdao/Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→Shipping

Q: What's your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.

Q: Does estyeracking have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products of estyeracking to fit at least one 20ft. container, which is about 15 tons.

Q: How does estyeracking charge tooling fee (cost of opening new mold)?

A: For the production of necessary tooling requirement, estyeracking charges the cost before the first order for opening new mold, and the cost will be partially or fully refunded after certain quantity of orders.