|

Weifang Estye Imp&Exp Co.,Ltd.

|

drive in storage racks

| Price: | 60.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

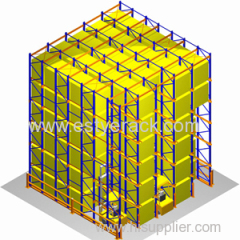

2011 drive in storage rack

1.drive in rack

2.Heavy duty drive in warehouse rack

3.High utility ratio

4.Assembled freely and adjustable

Drive in rack

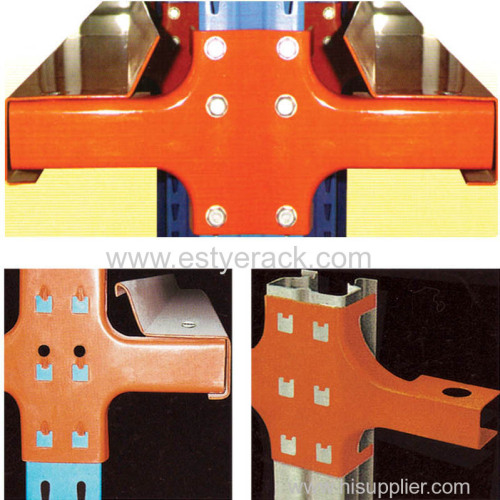

Drive in rack usually uses the pallets to storage the goods.The pallets can be put on the support arm one by one in the direction of the rack.In this way,it makes the high density of the space possible.And the goods can be unload from one side of the rack with an arrangement of Last-In-First-Out(LIFO).And the fork man can drive in to lift the goods out without special rails.it is suitable for the goods of less kind and large quantity.With a inserting structure,the upright frame of the drive in rack uses the assmbled structures.The rack depth should be within five pallets if the rack is next to the wall of the warehouse.When the rack is in the center of the warehouse,the rack depth should be within 10 pallets,which can make fork man effectively and dependable.Drive in rack is widely used in the fields of cold warehouse,foods and tobacco,which needs a high cost of the storage space of the warehouse.

drive in storage rack features:

1.Maximum space utilization, offer a highly efficient method of storing large quantities of similar loads

2.No aisles needed between rows of rack

3.Drive-In is "first in last out", great for seasonal moving items, Drive-Thru is "first in first out"

4.Forklift can drive to enter the rack system and place the load on structural rails

5.A cost-effective solution to high-density storage

6.Colors:Various of colors availble

7.Manually operated, it mainly include steel panels or wooden veneer

8.The height of each layer is easily to be adjusted by 75cm.

9.Drive-in storage rack can be customized based on customer's requirements

10.Suitable for storing metal components and widely used in the manufacturing industry

Warehouse Rack,storage rack,pallet racking,drive in rack

Drive in storage rack advantages including:

1) High density storage, low capital cost, no crushing of goods

2) No special handling equipment required

3) Suited to situations where individual selectivity is not important, and the product

rang is small, and the movement pattern is predictable, e.g. seasonal goods

where input and output take place at different times

4) Best suited to the high cost warehouse, e.g. cold room

| Size | Height (m) | Max load (kg) | Beam |

| 55*60*1.2 | 2 | 2 | 40*60*1.5 |

| 55*60*1.5 | 4 | 4 | 40*60*1.5 |

| 55*60*2.0 | 4 | 5 | 40*60*1.5 |

| 60*70*1.8 | 6 | 5 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*70*2.0 | 6 | 7 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*1.8 | 6 | 6 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*2.0 | 6 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*1.8 | 10 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*2.0 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*1.8 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*2.0 | 11.5 | 12 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 |

Special requirements:

1) Limited selectivity; last in, first out (LIFO) stock rotation

2) Truck guidance recommended for systems storing more than four pallets deeps

3) Some pallet types are unsuitable

4) Lanes to be filled / emptied in vertical layers

Required information from customers for quick quotation:

A) The warehouse drawing

B) The size of your warehouse

C) The size of shelving(length*width*height)

D) How many bays you want

E) How many layers you want

F) The loading capacity of each layer

G) The RAL color you want

FAQ

Q: What's your trading terms?

1) Payment terms: T/T 30% deposit after order confirmed, 70% balance paid against bill of lading. L/C O/A also available.

2) Lead time: normally in 20-25 days after deposit received.

3) Sample policy: samples are always available for each model. Samples can be ready in 7-15 days once payment received.

4) Shipping port: Qingdao/Shanghai / Nanjing China.

5) Discounts: we offer good discount for large quantity.

Q: How I can delivery my goods?

1) Sea freight: we will update sea freight once we know your sea port where goods will be delivered.

2) Agent designated by client: please tell us the contact detail of your shipping agent and we will arrange to deliver the items.

Q: What is your service?

1) Your inquiry related to our products or price will be replied in 12 hours.

2) Well-trained and experienced staffs to answer all your inquiries in fluent English.

3) OEM & ODM, any your customized racking we can help you to design product.

4) We have very experienced professional engineers to make best solutions.

Q: What to purchase your product?

Design drawing →Confirm drawing→Quotation→PI→Confirm PI→Arrange 30%deposit→Manufacture→QC inspect→Pay balance→Shipping

Q: What's your advantage?

1) Payment: we can do O/A 40-60 days.

2) Lead time: rush order we can fast delivery.

3) Factory price: factory direct sale competitive price.

4) Warranty: Two years warranty, the broken parts will be replaced and sent to you.

Q: Does estyeracking have MOQ (minimum order quantity) limitation?

A: No, but good quantity comes with good price. We recommend the order quantity for regular products of estyeracking to fit at least one 20ft. container, which is about 15 tons.

Q: How does estyeracking charge tooling fee (cost of opening new mold)?

A: For the production of necessary tooling requirement, estyeracking charges the cost before the first order for opening new mold, and the cost will be partially or fully refunded after certain quantity of orders.