|

Weifang Estye Imp&Exp Co.,Ltd.

|

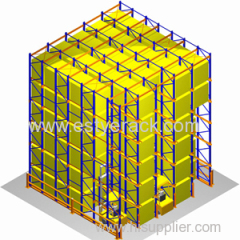

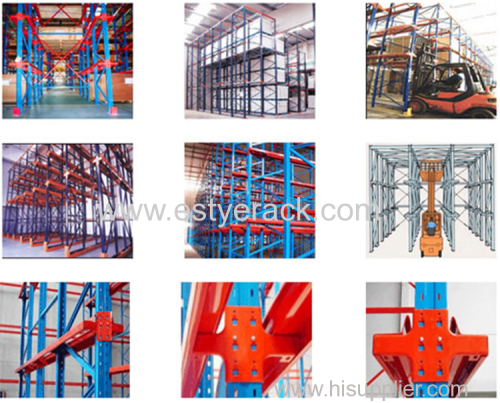

warehouse drive in racking

| Price: | 60.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Drive in racking:

1)High-density rack system;

2)Most cost-saving rack;

3)Install & dismantle easily;

4)Drive in & drive out.

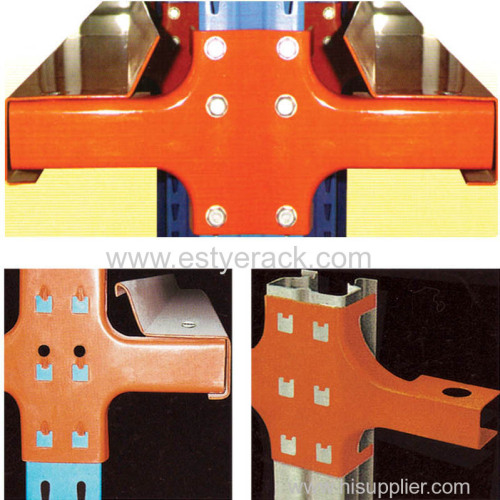

Drive in rack usually uses the pallets to storage the goods.The pallets can be put on the support arm one by one in the direction of the rack.In this way,it makes the high density of the space possible.And the goods can be unload from one side of the rack with an arrangement of Last-In-First-Out(LIFO).And the fork man can drive in to lift the goods out without special rails.it is suitable for the goods of less kind and large quantity.With a inserting structure,the upright frame of the drive in rack uses the assmbled structures.The rack depth should be within five pallets if the rack is next to the wall of the warehouse.When the rack is in the center of the warehouse,the rack depth should be within 10 pallets,which can make fork man effectively and dependable.Drive in rack is widely used in the fields of cold warehouse,foods and tobacco,which needs a high cost of the storage space of the warehouse.

| Upright size | Height (mm) | Max load for the upright frame (kg) | Beam szie |

| 55*60*1.2 | 2 | 2 | 40*60*1.5 |

| 55*60*1.5 | 4 | 4 | 40*60*1.5 |

| 55*60*2.0 | 4 | 5 | 40*60*1.5 |

| 60*70*1.8 | 6 | 5 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*70*2.0 | 6 | 7 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*1.8 | 6 | 6 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 60*80*2.0 | 6 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*1.8 | 10 | 8 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*90*2.0 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*1.8 | 11.5 | 10 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 | |||

| 70*100*2.0 | 11.5 | 12 | 50*80*1.5 |

| 50*100*1.5 | |||

| 50*120*1.5 | |||

| 50*140*1.5 |

| Product name | Heavy duty shelving drive in pallet racking | ||

| Color | RAL system | Material | Q235B steel |

| Usage | Warehouse Storage | Certification | RMI/CE/ISO/TUV/AS4084-2012 |

| Size | Customer Size | Structure | Assembled Freely |

| height | 1350mm - 12000mm | Capacity | Max. 21000kg/bay |

| width | 900mm - 1500mm | Thickness | 1.5mm - 3.0mm |

| Style | Drive In Rack | Packing | Customers'Request |

| Brand | ESTYE | Port | QINGDAO |

FAQ

1, What is the material being used for your products?

---Mild steel Q235, Q195

2, How is the goods being packed?

---Plastic banding + Stretch film wrapped, palletized for easy loading and unloading with a standard forklift truck or pallet jack.

3, What is the payment terms I can get?

---TT or L/C at sight, DP, etc.

4, What kind of finish do you provide for your goods?

---A. Electro galvanized/Zinc plated: the zinc serves as a sacrificial anode( indoor storage)

B. Hot dip galvanized: it forms a coating of corrosion-resistant zinc(indoor/outdoor and cold storage)

C.Powder coating: a type of coating that is applied as a free-flowing, dry powder(indoor/outdoor storage)

5. What is the loading capacity?

---In general, we have a light duty(100~300kg) model, medium duty(400~800kg) model and

heavy duty(1000~1700kg) model available for your choice.

6. Which product can be used in cold storage?

---Mobile rack, wire container, and roll cage are all widely used in cold storage.

7.I like your design, but couldn't find the right model from the products list, is custom size available?

---Yes, we do custom products and projects.

8 I would like to have my own design products and qty is not that big, is it ok?

---Yes, we can go with your custom design, no matter small or big qty, however, pls understand the cost will be different.

9 I don't have drawing or picture available for the custom products, could you design it for me?

Yes, we can make the best suitable design for you but do need to know the details, such as

a) dimension b) loading capacity c)stackability d)operation environment.

10 What is the minimum quantity I can order?

--1x20'GP - qty is variable depending on the size

11 What is your average production lead time?

--2-3 weeks against formal order and deposit.

12 Do I get any guarantee from your company?

-3~10 years warranty in the case that

A) Proper handling during operation, correctly forklift handling while stacking/unstacking

B) Overloading is prohibited

C) Environment request indoor, dry and not humid circumstance, do not contact with any corrosive chemical material (for zinc plated and powder coated products, no limitation for hot-dip galvanized).