|

Weifang Estye Imp&Exp Co.,Ltd.

|

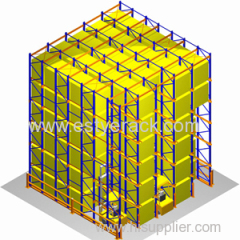

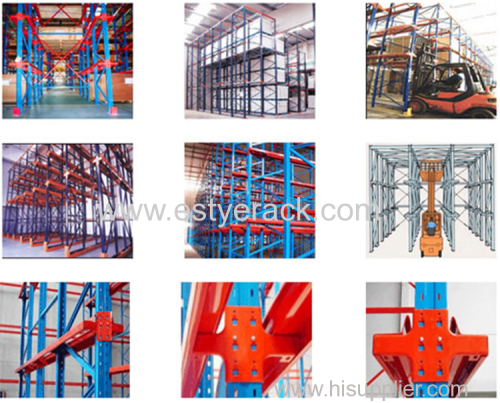

High Density Storage Rack Heavy Duty Drive In Pallet Racking System

| Price: | 60.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,Paypal,Money Gram |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.High volumes, few SKUs

2.Multiple access aisles eliminated

3.Extra control over inputs and outputs

4. powder coating or galvanized

High-Density Storage Rack Heavy Duty Drive-In Pallet Racking System

Drive-In pallet racking is a high-density storage solution ideal for high volumes of the same or limited SKUs. It is a Last-In/First-Out (LIFO) storage system with single-aisle access, allowing for a deep, compressed design. Drive-in pallet rack is easy to identify by its unique storage lanes equipped with horizontal rails that run the full depth of the rack. The system can store up to 10+ pallets deep per lane.

The first pallet is loaded in the last or furthest available pallet position leaving the most recently stored to be the first picked. However, you can also design the system with opposite side forklift entry and exit; this is called a Drive-Thru configuration.

Drive-in racking and drive-thru systems are exceptionally suited to large stocks of relatively few product types. Use this high density system to reduce overall square footage requirements by 35% or more, compared to a standard pallet rack configuration.

Advantages

LIFO (last in, first out) or FIFO (first in, first out) load methods

Deep lane storage reduces space usage, cuts costs and holds more loads

High volumes, few SKUs

Multiple access aisles eliminated

Extra control over inputs and outputs

More storage density instead of the direct access of Pallet Racks

Specifically designed for your pallets and forklifts

Drive-in pallet racks and drive-thru racks are roll-formed. Product is stored several pallets deep, and handling equipment enters the industrial rack structure to slot or extract pallets.

A drive-in pallet racking system uses a single input-output point per storage bay, creating last in, first out (LIFO) access. Meanwhile, a drive-thru system loads on one side and unloads on the other for first in, first out (FIFO) workflows.

Meet any storage requirement with our wide variety of bay heights and depths.

Material | Cold-rolled Steel |

Product size | Length: 2300 / 2500 / 2700 / 3000 / 3300 / 3600 / 3900mm Width: 900 / 1000 / 1100 / 1200mm Height: 2000-6500mm |

Thickness | column:1.5mm, 2.0mm |

| Load capacity | 1000-4500 kg per layer |

| Layers | 2-5 adjustable layers (can be custom made) |

Color | RAL color; As per customer's requirement |

Surface | Electrostatic spray surface |

Feature | Anti-rust, Corrosion-protection |

Guarantee period | 5 years warranty |

Remark | OEM&ODM accepted |

Relevant Certificate | CE |

Use area | Warehouse, factory, storage place |

Structure | Knock down structure, easy assembling, convenient for delivery |

Function | storage goods, rack, storage |

Product range | warehouse, storage place |

FAQ

Q1. What's your main products?

A: heavy duty selective pallet racking, drive in racking.long span shelving and so on.

Q2. What are your MOQ?

A:Different products has different MOQ.

If you need a quotation, please contact with us, we will check and give you a more exact and competitive price.

Q3. I'd like to buy one piece, is that possible?

A: It's ok! We do supply one for sample use. Hope you charge sample fee.

Q4. Do you accept the OEM or Custom Design order?

A: Yes, we do. Both are warmly welcomed.

Q5. How to proceed an order?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6: Do you offer guarantee for the products?

A: Yes, we offer 2-5 years warranty to our products.

Q7: Which country is your main export country?

A: At the moment, our main export regions are USA, Austrailia, Japan, Europe, Canada, South America, Mid-East etc.

Q8: How is my privacy protected?

A: Your privacy is important to us.

The guidelines we use for protecting the information you provide us during a visit to our website are listed in our Privacy Policy.